Torque Wrench Rentals

Hydraulic and manual torque wrench calibrations traceable back to NIST

We provide Hydraulic Torque wrenches that have a torque rating from 0-100,000 ft/lb. We provide both Standard and Low Clearance wrenches for all of your torque applications. Calibrations to both hydraulic and manual torque wrenches are also done on premises.

A hydraulic torque wrench is a tool used to tighten or loosen bolts or nuts with a high degree of precision and control. Here’s how it works:

Hydraulic pressure is applied to the wrench through a pump or other hydraulic system. The pressure is typically measured in pounds per square inch (PSI).

The wrench uses this hydraulic pressure to turn a piston or other mechanism that rotates the socket or bit on the end of the tool. This rotation generates torque, which is the force applied to the bolt or nut being tightened or loosened.

The hydraulic pressure can be adjusted to increase or decrease the torque being applied to the bolt or nut. This allows for precise control over the amount of force being applied.

Once the desired level of torque has been reached, the tool can be stopped and the bolt or nut is securely tightened or loosened.

Hydraulic torque wrenches are commonly used in industrial and construction settings, where they offer a high degree of precision and efficiency when working with large bolts or nuts.

HYDRAULIC TORQUE WRENCHES FIELD SERVICE • CALIBRATION

We stock a complete selection of

Multiplies – Custom Sockets – Specialty Tools

For immediate pickup or delivery

We offer unlimited field service, as well as torque wrench calibrations

Let’s Talk Torquenomics

Using only one hose and high strength die spring, this tool operates as fast as double acting tools at half the cost!!!

That’s why it’s”Torquenomical”

Unitorc-Specifications

• Knocker Wrenches

• Impact Sockets

• Solid Male Hex Drivers

• Custom Sockets

- Nickel/Chrome finish with ergonomic grip

- Tool does not have to be ‘turned down’ after use, providing convenience

- Torque setting locks on adjustable wrenches for repetitive applications

- Adjustment knob eliminates spring tension, so setting torque on adjustable wrenches is fast and easy

TORQUE TOOLS…

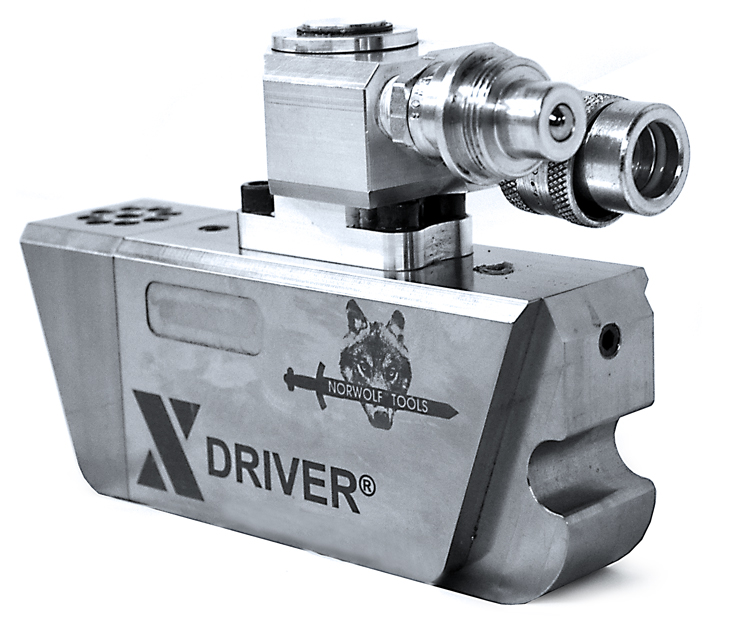

MISSING LINK • SWIVEL HAMMER • UNI-BAR • Z46 • BACKHOLD • STUDMATE • NORWOLF

WE ARE THE BOLTING EXPERTS!

Hydraulic Torque Wrenches

Hydraulic torque wrenches are specialized tools used to apply torque to nuts and bolts in various industries such as construction, manufacturing, and oil and gas. They work by utilizing hydraulic pressure to generate a high amount of force and torque, which is then applied to the nut or bolt being tightened.

This makes them an excellent choice for tightening large and heavy-duty bolts that require precise torque values. Hydraulic torque wrenches are available in different sizes and designs, depending on the application and the size of the bolts being tightened. They are easy to use and offer accurate and consistent results, making them a popular choice for many industries.

Skidmore first developed bolt tension calibration technology in the 1950s, and their units became the industry standard for testing high-strength bolts. In the same way that “Kleenex” became the generic term for tissues, “Skidmore” is the generic industry term used when referring to bolt tension calibrators. Today, both Skidmore-Wilhelm and Norwolf offer lines of bolt testing machines that are used for installations performed using manual, electric, pneumatic and hydraulic wrenches.

Skidmore bolt testing is required in applications such as steel buildings, bridges and similar structures. Skidmore bolt testing is performed for two main purposes:

- Preinstallation Verification (PIV) Testing, and

Rotational Capacity (RoCap) Testing